Pressure Filter Dryer

Pressure Filter Dryer is high-quality equipment designed for solid-liquid separation process, by filtration under pressure and vacuum drying, for the pharmaceutical, chemical, fine chemical and food industries.

Within the filtering applications, there are products which, due to their special hazardous or toxic characteristics, or simply to prevent cross-contamination, are more desirably treated in a hermetic way during their manufacturing process. Pressure filters by Tankki have been specially designed to answer these needs, guaranteeing the obtaining of pure substances which are free from polluting elements.

ADVANTAGE

- Hermetic production. No product is wasted and the risk of contamination is eliminated.

- Carrying out several operations using the same equipment: filtration, heating or cooling ,washing and/or drying.

- Obtaining high purity and homogeneous products independently of the granulometry.

- Space and installation costs reduction.

- Time reduction for cleaning, maintenance and filter element replacement.

FEATURES

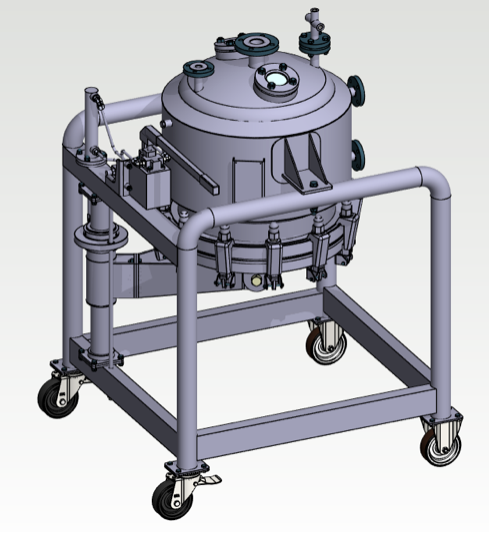

- Sizes in 150 , 380 and 450 liters

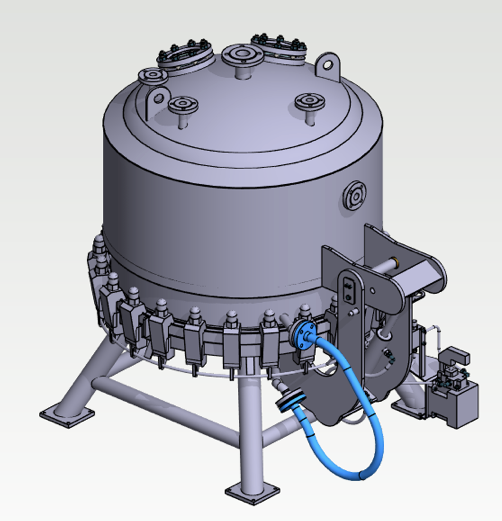

- Heating /cooling jacket on shell and bottom

- Various materials EN 1.4307, EN 1.4404, 904L Hastelloy C22

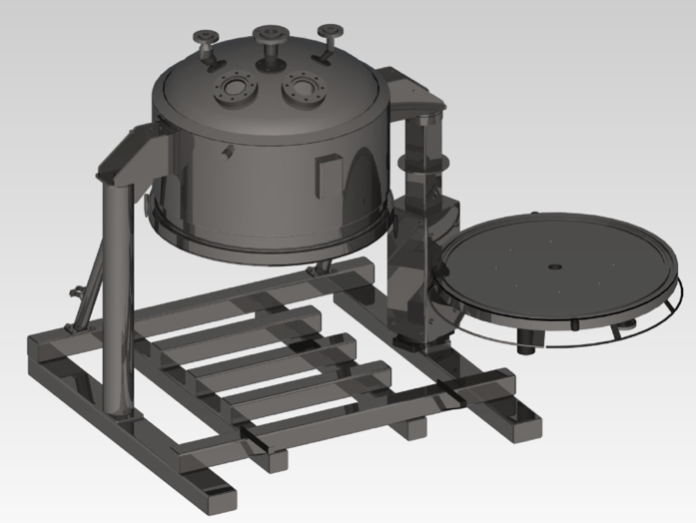

- Hydraulic operated lowering system for bottom to remove solid filtration

- Filtering screen support grid in various materials including Hastelloy C22 and PTFE with liquid guiding channels

- Various support types

- Frame with wheels on smaller units

- Hinged top construction

- Bottom plate lowerable and hinged to side

- Transportable by forklift

Interested to find out more? Get in touch!

Tel.

+358 6 510 1111

E-mail

tankki(at)tankki.fi

Tankki

TARGET GROUPS

CONTACT

Tankki Ltd

Oikotie 2

FI-63700 ÄHTÄRI

FINLAND

tel. +358-(0)6-510 1111

Spare parts inquiry: spareparts@tankki.fi