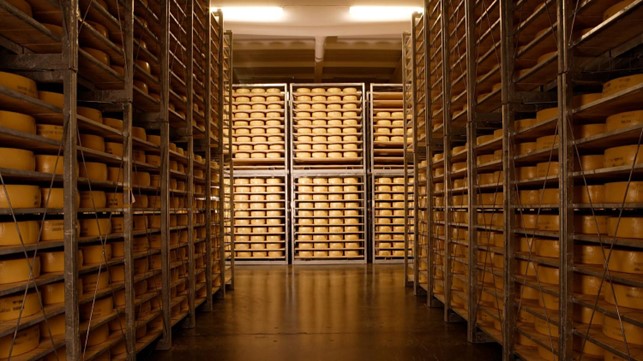

Norrmejerier has production facilities in Luleå, Burträsk and Umeå where roughly 200 million kg of milk is processed each year. Norrmejerier is a farmer-owned dairy association with operations in Norrbotten, Västerbotten and parts of Jämtland and Västernorrland counties. The association started in 1971 and the dairies in Umeå and Luleå produce drinking milk, various acidified products, cream, butter, cheese, Fjällfil® and Verum®. The dairy in Burträsk makes Västerbottensost®, the famous and mysterious cheese with a tradition and recipe since 1872. Norrmjerier’s Anders Hammarström says: “We were early pioneers when it came to brands, marketing and quality work. Our Västerbottensost® began to be sold and transported to Stockholm – by boat – as early as the 1870s and the W symbol with the crown was registered in 1910. We were also the first in Sweden to use side streams in our own biogas plant and thus take advantage the energy”.

The cheese is sold throughout Sweden and after the expansion in 2012, exports have also picked up. Västerbottensost® is now sold not only to Nordic countries but also to the Baltic countries, Switzerland, Germany, France, Spain, and other countries in Europe. The expansion has placed great demands on the dairy’s capacity at various levels. The need for increased cooling capacity was one such point.

Tankki has been a supplier to Norrmejerier for more than 20 years and in the meantime has supplied many process tanks to the dairies. At Norrmejerieri, a survey was started on how the increased cooling demand could be covered. Direct cooling and an ice water basin were among the options, which also included Tankki’s ice bank silo. The lack of space ruled out an ice water basin, and since the cooling demand was not constant throughout the day, we chose an ice bank silo for thermal energy storage. The cooling compressors are able to produce, with a constant load, partly direct cooling for production and partly charge the ice bank silo, which is used to smooth out fluctuations in the cooling demand and load peaks.

During the investigation, Tankki collaborated with Norrmejerier to assess, through simulations based on the dairy’s actual power output, how large a capacity a silo should be dimensioned for. In the assessment, Norrmejerier also took into account the need for refrigeration in a planned expansion. Based on the simulations, an ice bank silo with 3 radiators, each of which can be used separately and with a storage capacity of approx. 2200 kWh, was chosen as the model.

Anders Hammarström was responsible for the ice bank project and is after about a year operation very satisfied with the silo’s function. “Tankki’s simulation was an important aid in finding the right size according to the needs we could present”. The installation was according to Anders “well prepared and all assembly went quickly – everything mechanical was in place within a day”. Then the connection with an alcove to the business premises, pipe laying, electricity and water filling of the silo took place. In a final step, the silo was connected to Norrmejerier’s operating system including software to monitor ice thickness, flow and temperatures.

When asked if the silo has been difficult to integrate into other operations, Anders Hammarström answers “No, it went smoothly. It took some time for us to optimize the cooling compressors for the silo, but of course we had expected that”.

“We have many measurement points that we use as a basis for evaluation both in the dairy itself and especially in the silo. This information is retained and is important information for our owners, customers and our local community. Norrmejerier has so far made large investments to become a greener dairy. Tankki’s ice bank silo is an excellent additional tool for saving energy,” says Anders.